Paper-based materials—such as cardboard and corrugated cartons—have become ubiquitous in shipping and shopping. Despite plastic’s versatility and low cost, brands and box manufacturers explore raw materials and optimize paper products due to the public’s clamor for sustainable packaging.

If you ship out a high volume of orders weekly or daily, you must choose your paper packaging wisely. Safe shipping leads to memorable unboxing and lower product returns, resulting in customer loyalty and profitability.

This guide on cardboard and corrugated carton boxes aims to compare these two packaging types so you can select the most effective way to package your product or kits.

Distinguishing Cardboard Boxes from Corrugated Carton Boxes

It’s important to know what packaging box suppliers and printers refer to when they discuss cardboard and corrugated carton boxes. They’re folding box types that require assembly, unlike rigid or set-up boxes. Learning more about their individual qualities will help you decide which paper packaging suits your product.

Cardboard packaging (folding carton boxes)

Cardboard or folded carton boxes use heavy paper pulp or thick paper stock. Shoe boxes, cereal boxes, milk cartons, toilet paper rolls, and facial tissue boxes use this material.

Best uses: Cardboard boxes make great secondary packaging or the material surrounding your primary packaging, such as a glass bottle or plastic tub. Moreover, printers find it easier to print intricate designs on cardboard boxes than on corrugated ones due to the flat surface of the former.

Box Styles

Here are some of the most widely used styles for cardboard (folded carton) and corrugated carton boxes.

Cardboard (Folded Carton) Packaging

Straight tuck

Straight tuck boxes have top and bottom closures attached to the same side of the box. The closures—which typically feature slit locks near their end flaps—fold from front to back in the same direction.

Lock bottom

Lock bottom or 1-2-3 bottom boxes have a tuck top panel and bottom flaps that push into each other to lock. Its more secure bottom makes the packaging ideal for heavier items (wine, large candles, or electronics). The numeric name of the box refers to the three steps needed to assemble it.

Crash bottom

Crash bottom boxes, also known as auto-lock or auto-bottom boxes, have tuck-top closures and pre-glued bottoms, making them the most secure box type for heavy objects. Its base automatically folds and closes, unlike the lock bottom box, which needs manual assembly.

Reverse tuck

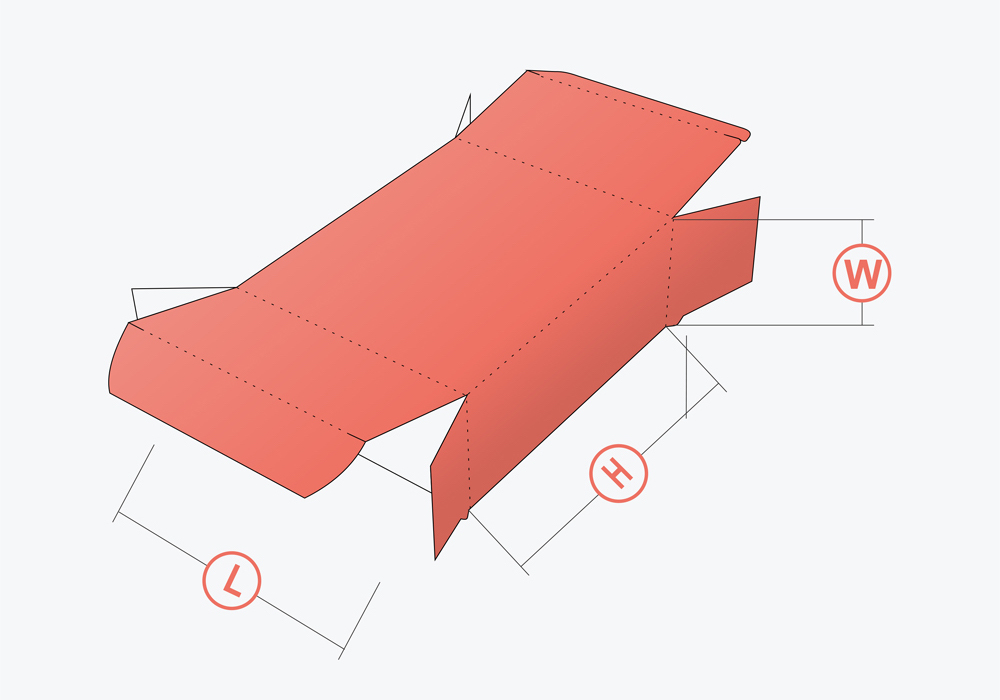

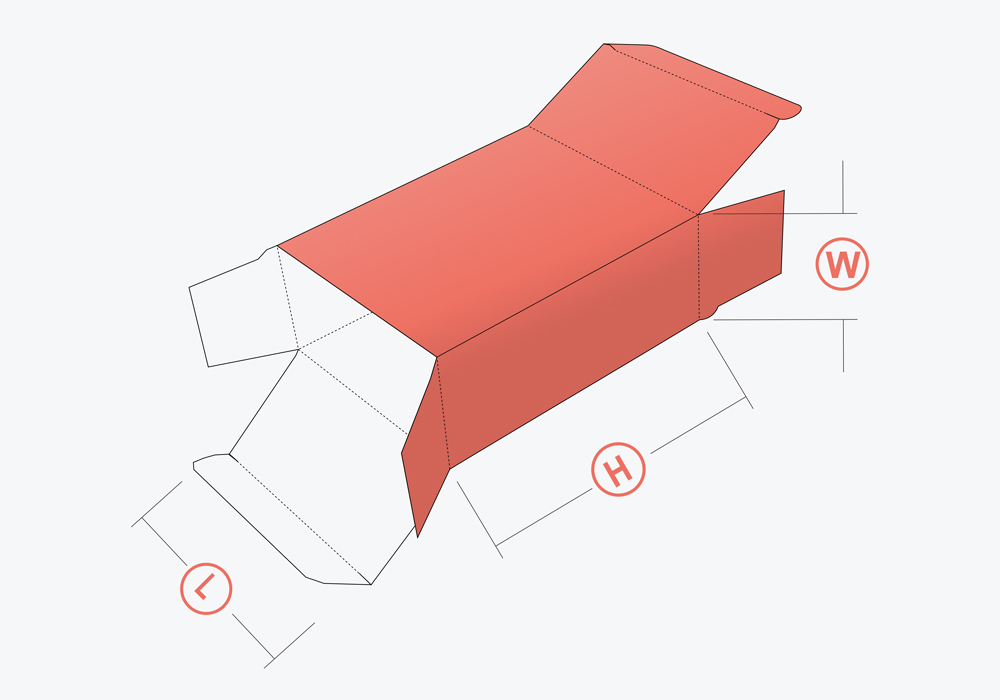

A reverse tuck box’s top and bottom closures are on opposing sides of a box so that they fold in opposite directions.

One-piece tuck top

One-piece tuck-top boxes are similar to mailer boxes, only they’re made of paperboard. They have a top opening with tucking tabs that fold into the bottom of the box. You’ll find many baked goods like donuts sold in this box style.

Two-piece (Simplex or Kwikset tray)

A two-piece box consists of a tray and a lid with double-wall structures. They can come with inserts, making them a highly recommended solution for sweets, luxury products, or kits.

Hanger (hang tab) style

A hanger box is a reverse tuck box with a hanger panel extending from the back, allowing you to hang it on a hook or stand for retail display.

Gable top (handle or carrier box)

Gable top boxes have a crash bottom and a top handle. It’s a popular style for packaging gifts and food.

Pillow style

A pillow box has a curved shape with flap closures on the sides that bend in. They can contain lightweight and small products, such as jewelry, hair accessories, soaps, party favors, or event giveaways.