When we talk about packaging, one of the aspects that are less explored is package thickness.

How thick or thin your packaging is can have an impact on its durability, protectiveness, and aesthetic appeal.

Understanding package weight and the different factors that need to be considered can help you design effective packaging that works for your product needs.

We’ll look at key terms used to describe packaging, the unit systems used, how to convert and compare units and weight as well as how that impacts your overall packaging.

We’ll first look at some definitions to help you understand how to determine cardboard thickness for packaging.

What are GSM unit and PT unit?

First things first, the common terms you’ll hear around packaging are PT and GSM so let’s break those down.

PT stands for point and GSM stands for grams per square meter.

If you’re thinking about GSM vs. PT, both terms are used to measure the packaging stock and to determine how much material stock is needed to create packaging tailored to your products’ needs.

Another measurement you’ll find is lb or pounds of the weight of the paper.

This is measured by using one ream (i.e., 500 sheets) before it is cut.

These are the basic units used in the context of packaging stock.

We’ll now take a closer look at each one individually to help differentiate between GSM and Point.

The Point System (PT)

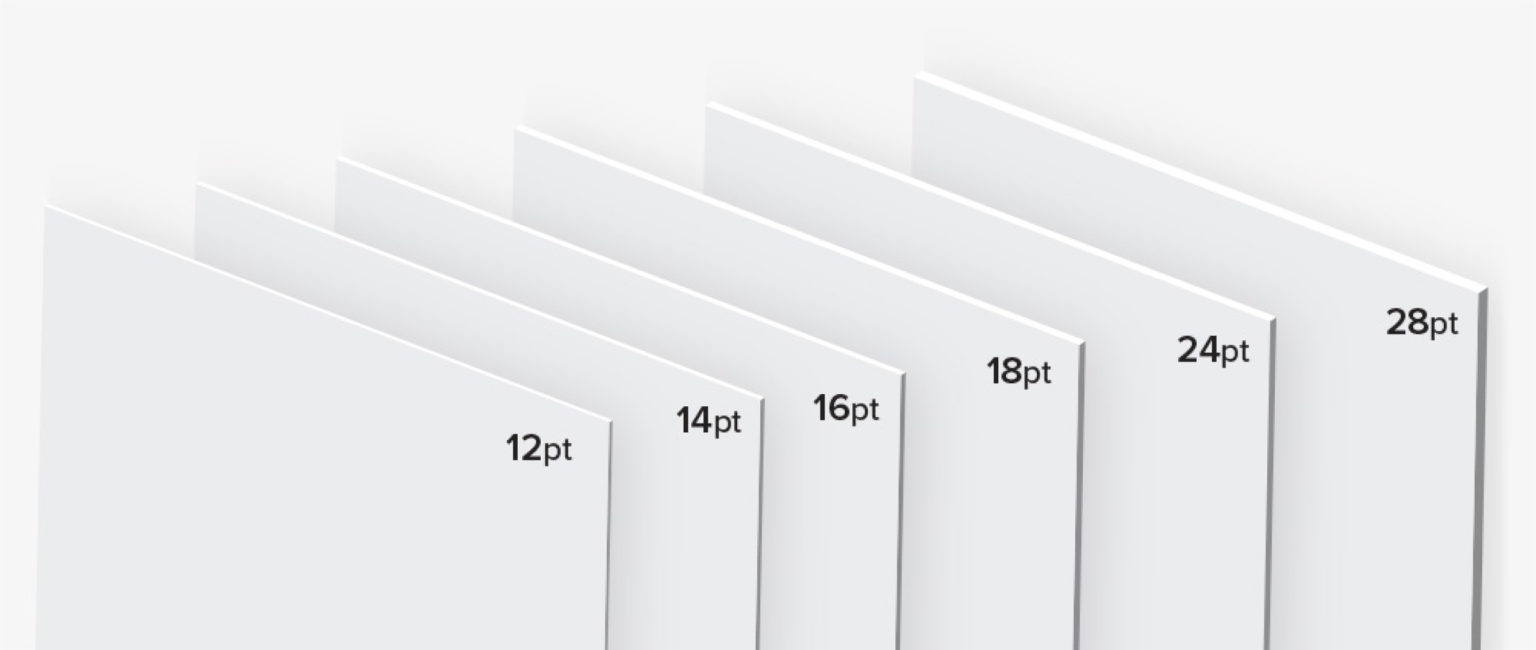

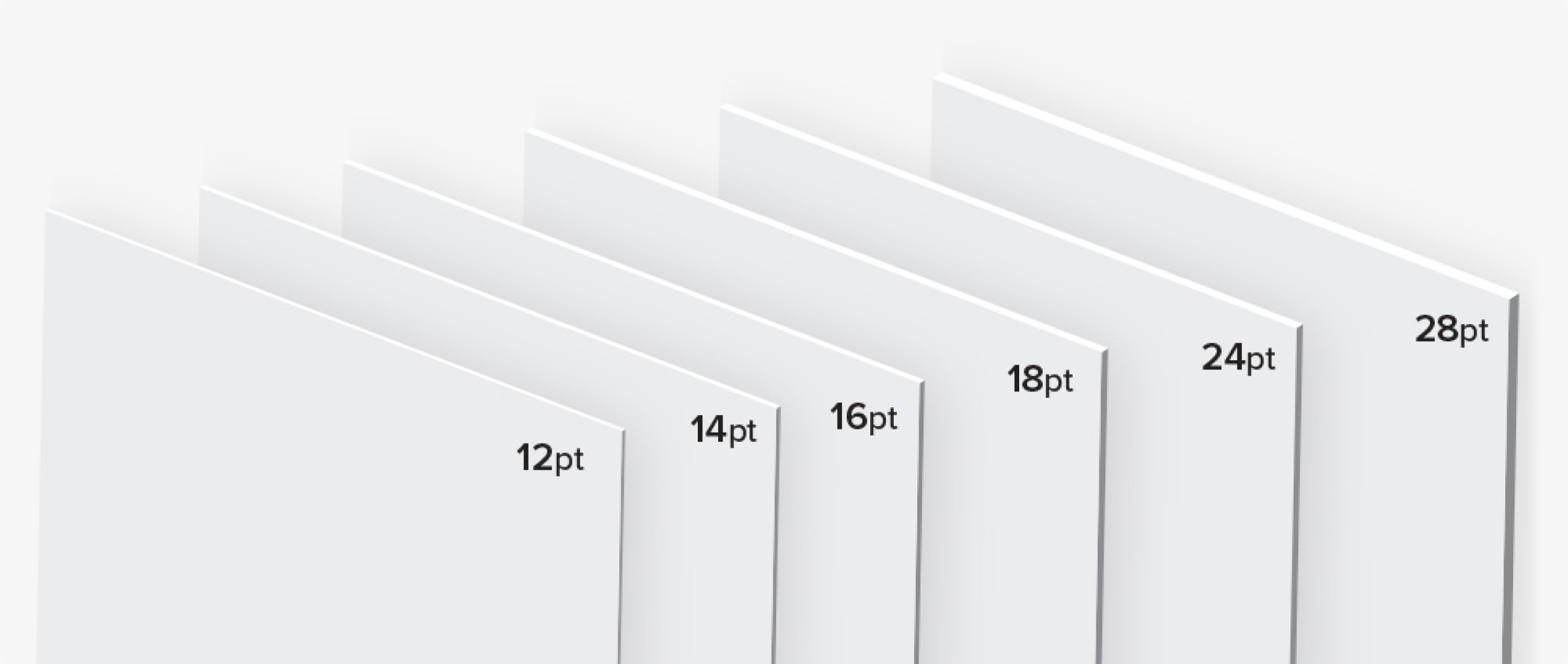

As we’ve discussed before, points are used as a way to demonstrate the thickness of a sheet of paper, including packaging corrugated paper.

The thickness is measured using calipers, with each point representing 1/1000th of an inch.

As you browse packaging options, you’ll see that many use the point system to describe the thickness, such as 8 point and going up to 16 point.

The measurement that you see can help you determine how thick the stock is and give you a better idea of the protective qualities it has to offer.

The higher the PT the thicker.

Grams per Square Meter (GSM)

Grams per square meter (GSM) is essentially the metric equivalent of the point system as it uses centimeters and meters for its prime measurement.

It can be confusing as there is no straightforward way to convert measurements from one system to another.

This is because grams per square meter (GSM) looks at paper weight, length, and breadth rather than just the thickness and height.

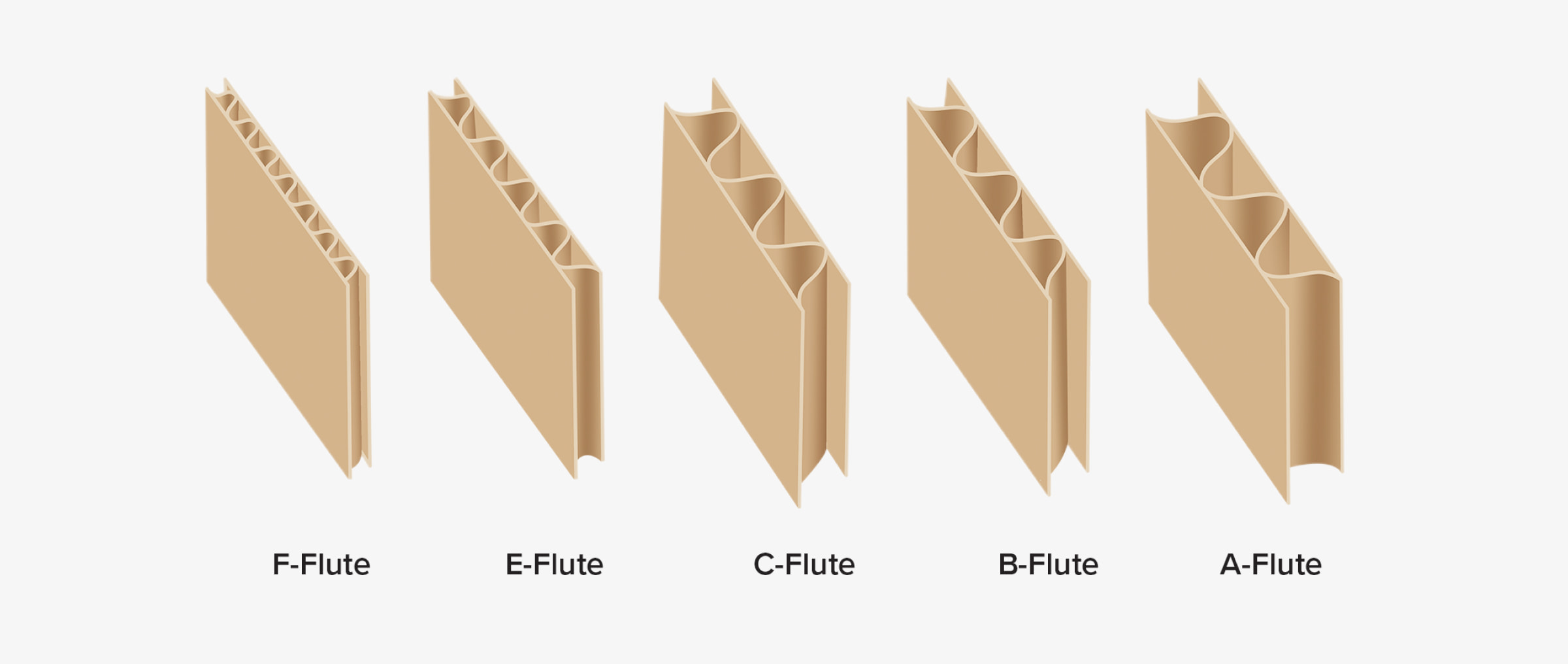

Bear in mind that some packaging materials may seem thick, but that doesn’t necessarily mean they are heavier.

For example, when you think about the corrugated thickness for packaging, you can have a corrugated fiberboard that feels thicker, but it won’t necessarily be heavier.

However, the higher the GSM unit is, the more thick and heavy the paper will be with GSM.

Generally, high-quality paper tends to have a higher GSM since it’s more durable, and images tend to look better when printed on.

How to Compare Paper Weights and Thickness

Although the systems can be confusing between the US and metric, the core thing to remember is that the GSM system includes weight as part of its measurement for paper.

Knowing your packaging material’s weight and thickness is particularly helpful when measuring corrugated paper thickness and cardboard thickness for packaging.

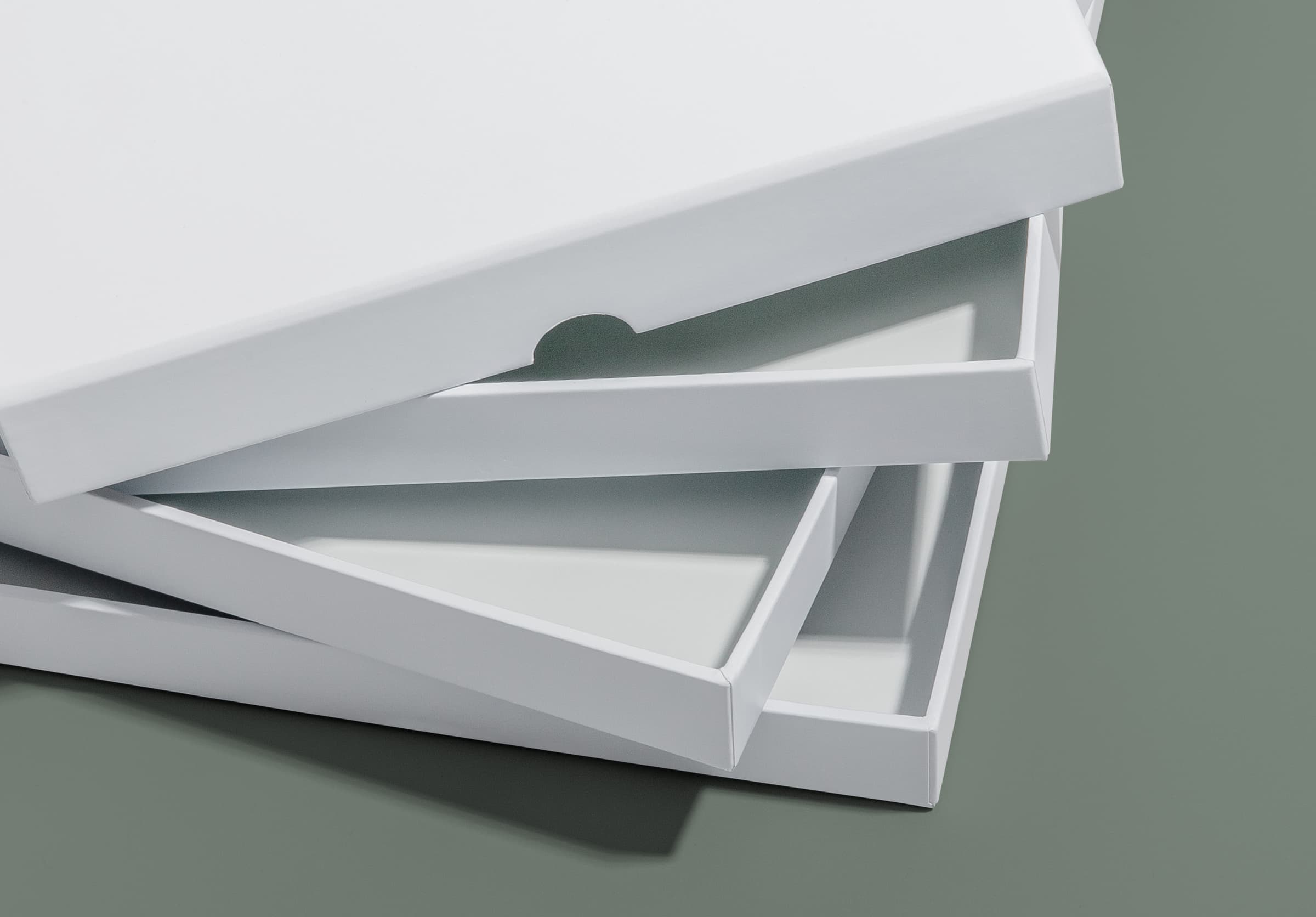

The thickness and weight can help you choose the best packaging thickness that will give your customers a great unboxing experience and is durable enough that it won’t get damaged during long transit and shipping.

You can work with packaging experts to better understand the pros and cons of different weights and thicknesses and how that will affect your packaging material cost and shipping charges.